Ad

related to: What is a manufacturing change?Built to drive growth and efficiency in shops of all sizes. Schedule a demo to learn more. Make more accurate quotes. Spot manufacturability issues before they cost you time & money

- Ideal for Machinists

Manual quoting hurts your business

by slowing you down and leaving...

- Win More Business

Unlock your shop's potential with a

single centralized platform...

- Fewer Errors, More Speed

Get a demo of the #1 estimating &

quoting software in manufacturing

- Smarter, Faster Quoting

See how the #1 manufacturing

estimating & quoting software...

- Pricing

Plans Tailored to Help Your

Shop Grow at Every Stage

- No More Quoting...

Paperless Parts is the #1

estimating and quoting software ...

- Ideal for Machinists

Search results

News about manufacturing, UK, US Dollar Index

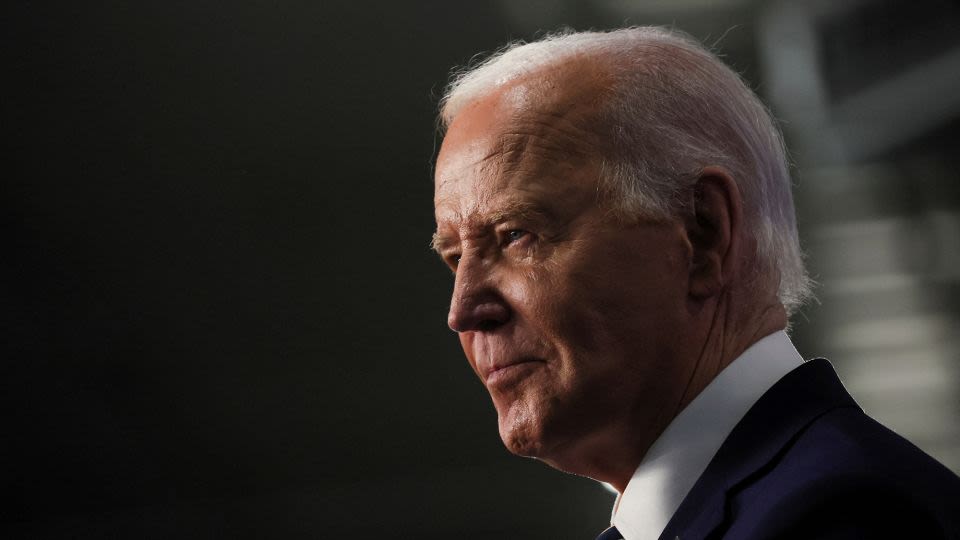

News about Senate Democrats, Electric Cars, Biden's record

Also in the news

People also ask

What is manufacturing change process?

What is change management in manufacturing?

Why should manufacturing changes be documented?

What makes a good manufacturing change process?

Manufacturing change management is the execution of a consistent and systematic approach to the implementation of changes in product design or manufacturing processes. Effective change management minimizes disruption to the business and does so without compromising quality or efficiency.

Apr 30, 2024 · Change management in manufacturing is a systematic approach to planning, implementing, and evaluating changes in external and internal processes. It is critical for enhancing efficiency and agility, fostering innovation, boosting employee morale, and maintaining industry competitiveness.

- Manufacturing Change Management: What Does The Process involve?

- Three Tips For An Efficient Manufacturing Change Process

- Make Your Manufacturing Change Processes Work For you.

The first step toward an effective manufacturing change process is understanding how change is initiated and managed in your organization. A manufacturing change typically starts when a shop floor worker, supervisor or engineering team member identifies an issue on the manufacturing line—like glue failure or a line backup—and it ends when a solutio...

Tip 1: Cultivate a relationship between engineering and manufacturing.

To improve your manufacturing change process, create an environment that encourages a strong relationship between your engineering and manufacturing teams. Building these relationships can take time–and is by no means is easy—but it will impact your change processes significantly. Engineers can participate in the manufacturing process by spending time on the manufacturing line. While roaming the floor, engineers get face time with line workers and leads, and receive feedback and comments they...

Tip 2: Make it easy to communicate in your manufacturing change process.

In addition to encouraging strong cross-functional relationships, provide easy ways for everyone to discuss manufacturing changes so you can address issues on the line in an efficient manner. As stated above, face-to-face contact between engineering and manufacturing teams will provide opportunities for information exchanges to happen naturally. But because engineering can’t be on the floor every minute of the day, it’s important that your assembly line workers and leads have other ways to do...

Tip 3: Keep your manufacturing change cycles short.

With short change cycle times, you’re more likely to achieve your time to market goals. Create change boards that include key stakeholders and make it easy for them to participate in the change process. This way changes can be reviewed and approved quickly. In many cases, the manufacturing change process tools you use will impact your change cycle times. Paper change forms offer a free way to capture, document and process changes, but they fall short when it comes to efficiency. With dedicate...

Manufacturing a product as cost-effectively as possible is a goal for most small to mid-size manufacturers. Because problems on the manufacturing line can increase costs and slash your revenue stream, it is critical to address problems efficiently. To review—if you want improved efficiency and productivity on your manufacturing line, follow these t...

Manufacturing change management enables smoother transitions in the workplace, focusing on clear communication and support for all employees. It involves effective planning, transparent communications, mitigating resistance, equipping sponsors and managers for their roles, and more. This approach helps employees adapt to new customer demands ...

Manufacturing change process is a subset of engineering change management. Engineering change management involves creating, reviewing and gaining formal approval for engineering change requests (ECRs), engineering change orders (ECOs), and engineering change notifications (ECNs).

An engineering change order (ECO) is a formal review process of proposed engineering changes to an established baseline that will impact form, fit, or function. An ECO, at minimum, will list all the affected components and will provide the reasoning behind the proposed changes.

Mar 23, 2023 · In manufacturing, change management involves continuing to produce in the most cost-effective manner possible, while optimizing production processes and adopting a flexible attitude to change (labor shortages, raw material shortages, supply chain disruptions, technological innovations, etc.).

Ad

related to: What is a manufacturing change?Built to drive growth and efficiency in shops of all sizes. Schedule a demo to learn more. Make more accurate quotes. Spot manufacturability issues before they cost you time & money