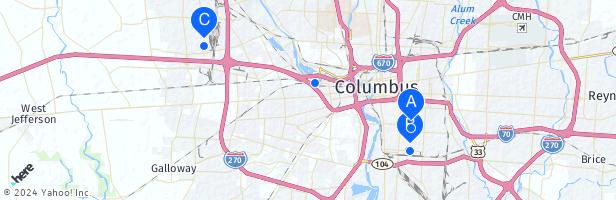

Search results

Discover more placesNear Columbus, OH

Refine results for Metal Industries

Related businesses

Steel is primarily produced using one of two methods: Blast Furnace or Electric Arc Furnace. The blast furnace is the first step in producing steel from iron oxides. The first blast furnaces appeared in the 14th century and produced one ton per day.

Mar 20, 2024 · It was one of the biggest employers, a driver of economic growth, and it shaped our national security. Cars, weapons, skyscrapers... all needed steel.

May 21, 2021 · Slag is scraped off liquid steel at a Cleveland-Cliffs steel mill in Burns Harbor, Ind. The boom has led the domestic steel industry to once again hire workers. Taylor Glascock for The New...

There are two main types of steel mills. The traditional large integrated steel mill, which reduces metallic iron from ore (iron oxide) and makes it into pig iron and steel, has been steadily declining in importance for decades in the US.

May 17, 2022 · occupied by integrated steel mills—purchase steel slabs and roll them into a variety of products, such as sheet and pipe. Slabs used for this purpose typically are imported, as most domestic mills

May 13, 2024 · The steel production process is a multi-faceted journey that begins with extracting and processing iron ore, a primary raw material essential to steel making. Iron ore undergoes a series of refining steps to extract the iron content, culminating in the creation of molten iron.

May 14, 2024 · The American steel industry isn’t what you’d think. And for good reason. For over a quarter century, electric arc furnace (EAF) steelmaking has made steel greener, safer and the most energy efficient in the world today.